Builder finds Firth HotEdge easy as…

It’s common to get caught up with design aspects of your home that will affect how it performs, such as wall and ceiling insulation, double or triple glazing, cooling and heating systems etc. But what about the foundations?

Having a warm, dry and healthy home is the desire of all homeowners, as it is for architects when designing homes on behalf of their clients. And it starts with the foundations.

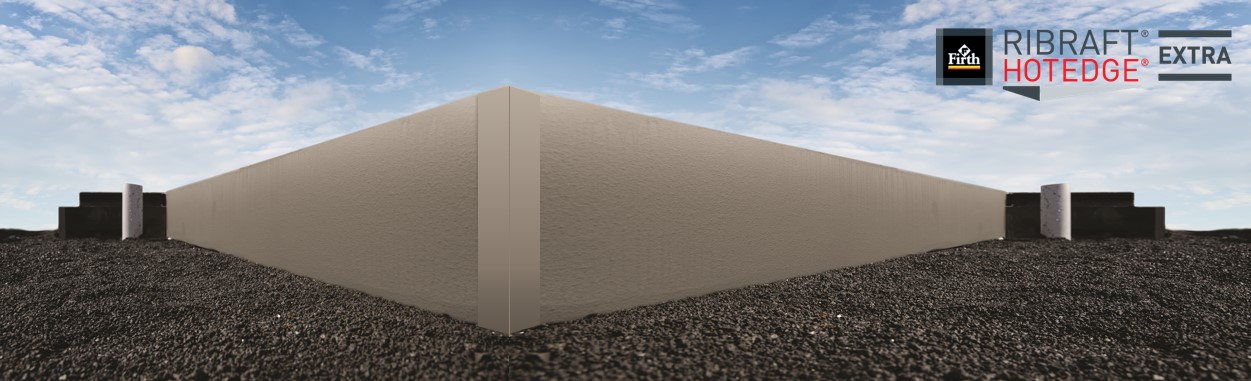

Firth’s RibRaft® HotEdge® is a fully integrated slab edge insulation system that will help achieve that warm, cosy home and it’s as easy as … 1,2,3 … because the hard work has been done.

Firth helps builder with their first HotEdge® installation

Rotorua builder CH Builders has installed RibRaft HotEdge in a spec home he had designed and built himself, while in between projects for clients.

“I wanted to use RibRaft® HotEdge as a selling point for this house to show that it meets all the criteria for a warm, dry, healthy home,” explains Charles Hubbard, Director of CH Builders.

“I arranged for Greg Illing, our Construction Systems Specialist for HotEdge, to come down to Rotorua to assist Charles and his guys with the installation of HotEdge® as it was the first time he had used this product,” says Mike Price, Sales Consultant (Rotorua) for Firth.

“When Mike offered Firth’s help with the installation, we saw it as a perfect opportunity for us to be able to hold a training morning to upskill our staff with the new Firth HotEdge,” adds Charles. “I think having Mike Price and then Greg come down for some training was 100% worth it as we now know how to install it correctly and it proved to be really easy.”

Charles’s hunch has paid off … he’s already sold the house and is moving on to the next one!

Why choose RibRaft® HotEdge

“Our slab insulation products help architects and engineers achieve H1 compliance and more with their designs,” explains Wade Hargreaves, Senior Product Marketing Manager at Firth. “They can create warmer, drier homes for kiwis by eliminating cold spots at the slab/wall thermal bridge where moisture can form and lead to mould issues. We’ve developed free online tools to make it easier to specify our systems in their designs. These tools save time which means a cost saving for them.”

“We have a BRANZ tested (ST18050) bottom plate anchor solution with HotEdge Extra and 90mm timber framing, which achieved 15kN and therefore meets common bracing system requirements. This gives architects, engineers and builders considerable confidence and peace-of-mind when specifying or installing our products.”

Need help or want to know more? See below for some handy tips and info or contact us on 0800 FIRTH1.

Tools to help:

- HotEdge R-value Calculator (for slab A/P ration design calculations) https://www.firth.co.nz/r-value-calc/

- WaffleSuite (for more complex foundations designs with X-Pod) https://nz.wafflesuite.com/login

- BRANZ Tested (ST18050) anchor solution for 90mm timber framing bottom plate

- 3D Thermal Modelling to prove R-values for HotEdge and HotEdge Extra

“We also have a dedicated technical support team to help architects and engineers with specific design and specification questions or swap-outs,” adds Wade. “This is a game changer for architects and engineers.”

Technical points to note:

- HotEdge solutions are designed for use with all cladding systems to help designers/engineers achieve foundation compliance with H1.

- HotEdge (BV) for brick cladding and HotEdge Extra for non-brick - BRANZ Tested (ST18050) bottom plate anchor solution for 90mm timber framing

- Testing achieved 15kN. Ie meets proprietary bracing system requirements where other products don’t - Quality edge insulation for RibRaft slab foundations

- Closing a building’s thermal envelope helps reduce cold points at wall/slab junction (cold spots = mould spots) - HotEdge (BV) has been in the market for 5+ years

- Proven effectiveness based on HotEdge 3D thermal modelling

- Be wary of imitations that have not been tested or have verified R-values - Quick and easy to install (time/cost saving for installers)

Compared to insulated, permanent formworks or products that need plastering - HotEdge Extra is 100% compatible with HotEdge (BV) for building designs that have multiple cladding types

- Durable pre-plastered, extruded XPS slab edge insulations boards with ready-to-paint surface for reduced finishing time/clean up

- Up to 10 x stronger than EPS, more resistant to moisture than PIR

- Performs an aesthetic function by providing a tidy and paintable finished surface for concrete slab perimeters